The Future of Rubber Recycling

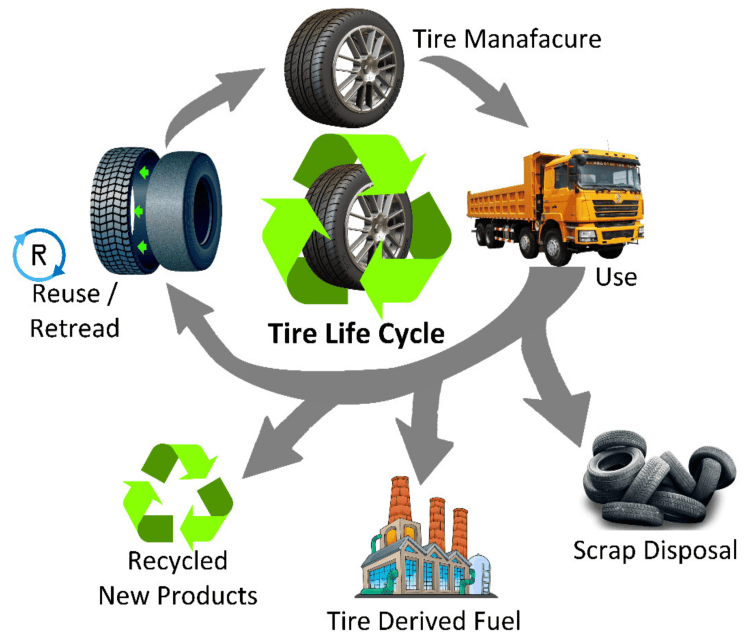

In our modern industrialized world, rubber plays a pivotal role in various aspects of everyday life. From automobile tires to industrial seals, from footwear to consumer goods, rubber products are ubiquitous. However, with the widespread use of rubber comes a significant environmental challenge: waste rubber disposal. The improper disposal of rubber products contributes to environmental degradation, posing risks to ecosystems and human health alike.

The Challenge of Waste Rubber

Rubber, a versatile material derived primarily from natural sources like latex from rubber trees or synthetic polymers, poses a unique challenge when it comes to disposal. Due to its durability and resilience, rubber products can take decades or even centuries to decompose naturally. Improperly discarded rubber products, such as tires, end up in landfills or are illegally dumped, creating eyesores and environmental hazards.

Environmental Impact

The environmental impact of waste rubber is multifaceted. When disposed of improperly, rubber products can leach harmful chemicals into the soil and water, leading to contamination. Moreover, the combustion of rubber releases toxic gases and particulate matter into the atmosphere, contributing to air pollution and potentially harming human health.

Economic Opportunity

Despite the challenges posed by waste rubber, there exists a significant opportunity for innovation and economic growth through recycling. Recycling waste rubber not only mitigates environmental harm but also creates jobs and economic opportunities in the burgeoning field of sustainable materials.

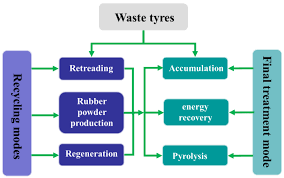

Methods of Rubber Recycling

Mechanical Recycling

Mechanical recycling is one of the primary methods used to recycle waste rubber. This process involves shredding or granulating rubber products into smaller pieces, which can then be used as raw material in various applications. One common example is the recycling of end-of-life tires into crumb rubber, which can be used in sports surfaces, playgrounds, and as an additive in asphalt for road construction.

Devulcanization

Devulcanization is a process that involves breaking down the sulfur crosslinks in vulcanized rubber to restore its elasticity and processability. This method allows for the recycling of rubber products that would otherwise be difficult to reuse due to their vulcanized nature. Devulcanized rubber can be reprocessed and used in the manufacturing of new rubber products, thereby extending the lifecycle of the material.

Pyrolysis

Pyrolysis is an advanced recycling method that involves heating waste rubber in the absence of oxygen to break it down into valuable products such as pyrolysis oil, carbon black, and syngas. Pyrolysis offers a promising avenue for recycling waste rubber into high-value products that can be used in various industrial applications, including energy generation and chemical manufacturing.

Chemical Recycling

Chemical recycling encompasses various processes that use chemical reactions to break down waste rubber into its constituent molecules. These molecules can then be used as feedstock for the production of new polymers or other chemicals. Chemical recycling holds promise for creating a closed-loop system where waste rubber is continuously recycled without losing material properties.

Applications of Recycled Rubber Products

Construction Materials

Recycled rubber products find extensive use in the construction industry. Crumb rubber, for example, is used as an additive in asphalt pavements to improve durability, reduce road noise, and enhance skid resistance. Rubberized concrete, which incorporates recycled rubber aggregates, offers improved flexibility and impact resistance compared to traditional concrete.

Consumer Goods

Recycled rubber is also used in the manufacturing of consumer goods such as footwear, mats, and flooring. By incorporating recycled rubber into these products, manufacturers can reduce their environmental footprint while offering consumers sustainable alternatives.

Energy Generation

Pyrolysis oil derived from waste rubber can be used as a renewable fuel source for energy generation. The high calorific value of pyrolysis oil makes it suitable for use in industrial boilers, furnaces, and power plants, providing an environmentally friendly alternative to fossil fuels.

Challenges and Opportunities Ahead

While significant progress has been made in rubber recycling technologies, challenges remain. One of the key challenges is the collection and sorting of waste rubber, which can be costly and labor-intensive. Additionally, ensuring the quality and consistency of recycled rubber products is essential to gaining consumer trust and expanding market opportunities.

However, the future of rubber recycling is bright, with ongoing research and development efforts focused on improving recycling efficiency and expanding the range of applications for recycled rubber products. Innovations in chemical recycling and advanced materials science are paving the way for a circular economy where waste rubber is transformed into valuable resources.

Conclusion

In conclusion, waste rubber recycling represents a critical component of sustainable resource management in the 21st century. By recycling waste rubber into new products and materials, we can reduce environmental pollution, conserve natural resources, and create economic opportunities. Continued investment in research, infrastructure, and public awareness is essential to realizing the full potential of rubber recycling and building a more sustainable future for generations to come.

How Paper Recycling Helps the Environment

This blog explores the multifaceted ways in which paper recycling contributes to environmental conservation, examining its benefits, processes, challenges, and future prospects.

“How the UK Transforms Plastic Waste into New Products”

Plastic recycling is a critical component of waste management in the United Kingdom, given the extensive use of plastics in everyday life. Understanding the process, challenges, and advancements in plastic recycling helps appreciate the efforts toward environmental sustainability and the circular economy. This blog provides an in-depth look at how plastic is recycled in the…

The Environmental Benefits of Paper Recycling

This blog explores how paper recycling helps the environment, delving into its benefits, processes, and the role each of us can play in making a difference.